Achieve Peak Performance

Many automotive engineering teams face issues with traditional weld fasteners, which is why we created a free cost calculator to help you evaluate potential savings and ensure you do not waste precious energy and resources.

Many automotive engineering teams face issues with traditional weld fasteners, which is why we created a free cost calculator to help you evaluate potential savings and ensure you do not waste precious energy and resources.

Recoup Time

lost to inefficiency

Remain The OEM Leader

people trust

Eliminate Frustration

connected to quality Issues

If you’re like many of the OEMs and fabricators we’ve worked with, you and your engineering team are spending valuable time and energy on all of the secondary processes associated with weld fasteners and it’s impacting your bottom line.

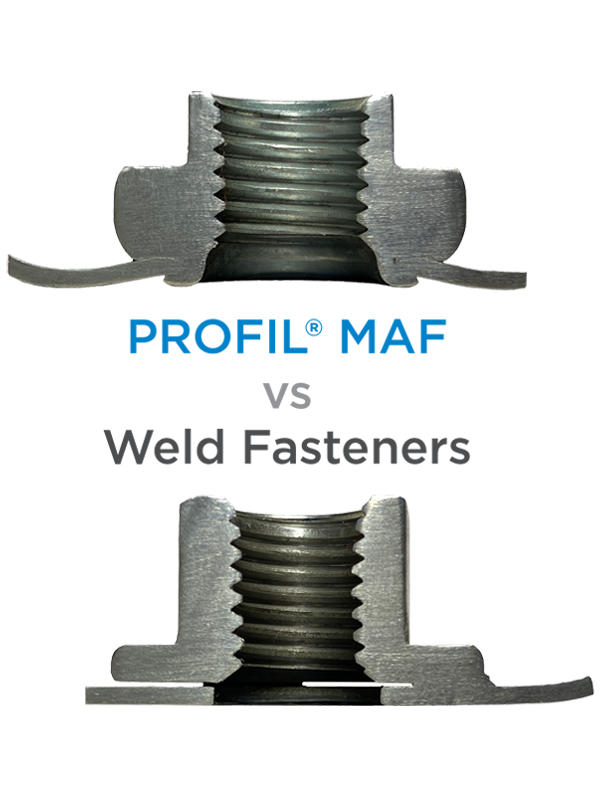

At PROFIL®, we design and manufacture Mechanically Attached Fasteners for highly engineered automotive applications. We’re driven to help you cut costs, improve performance, and become more efficient in the process which is why we created a free cost calculator to help you evaluate potential savings and ensure you do not waste precious energy and resources.

Easily enter everything to get your answers.

You’ll see what’s working well and where things can be optimized.

Implement needed changes from your results and enhance your performance.

We pair the best quality MAFs with ongoing support and service. You feel helpless when you’re stuck without a solution, which is why we operate as your trusted partner. When you encounter a hiccup, we’re standing by with technical assistance that leads to solutions.

Use the Weld vs. In-Die Cost Calculator below to determine the potential cost savings gained by using PROFIL® In-Die Fasteners for your next program.

| Savings | |

|---|---|

| Per Nut | |

| Per Bracket | |

| Annual | |

| Remaining Life of Program | |

| Process | Pedestal Weld Cell Installation (Weld Nuts) |

|

|---|---|---|

| Life of Program (years) |  |

|

| Bracket Volume Per Year | ||

| Nuts Per Bracket | ||

| Nut Volume Per Year | ||

| Years In Production | ||

| Brackets Per Stroke/Cycle | ||

| Cycle Time (seconds/bracket) | ||

| Machine Speed (SPM/CPM) | ||

| Throughput @ 90% (brackets/hr) | ||

| Hours Per Shift | ||

| Work Days Per Year | ||

| Work Hours Per Year (1 Shift) | ||

| Shifts Required |

| Cost Element | Quantity | Cost/Each | Total | Cost/Nut |

|---|---|---|---|---|

| Nut | $ | |||

| Capital | $ | |||

| Tooling | $ | |||

| Cell Floor Space - Sq. Foot | $ | |||

| Direct Labor Per Hour | $ | |||

| Operating Expense Per Hour | $ | |||

| Indirect Labor Per Hour | $ | |||

| Subtotal | ||||

| SG&A | % | |||

| Markups | % | |||

| Total |

| Process | In-Die Installation (PROFIL NUTS) |

|

|---|---|---|

| Life of Program |  |

|

| Bracket Volume Per Year | ||

| Nuts Per Bracket | ||

| Nut Volume Per Year | ||

| Years In Production | ||

| Brackets Per Stroke/Cycle | ||

| Cycle Time (seconds/bracket) | ||

| Machine Speed (SPM/CPM) | ||

| Throughput @ 90% (brackets/hr) | ||

| Hours Per Shift | ||

| Work Days Per Year | ||

| Work Hours Per Year (1 Shift) | ||

| Shifts Required |

| Cost Element | Quantity | Cost/Each | Total | Cost/ Nut |

|---|---|---|---|---|

| Nut | ||||

| Capital | $ | |||

| Tooling | ||||

| Cell Floor Space - Sq. Foot | ||||

| Direct Labor Per Hour | ||||

| Operating Expense Per Hour | ||||

| Indirect Labor Per Hour | ||||

| Subtotal | ||||

| SG&A | % | |||

| Markups | ||||

| Total |

PANEL P/N

FASTENER P/N

DATE P/N